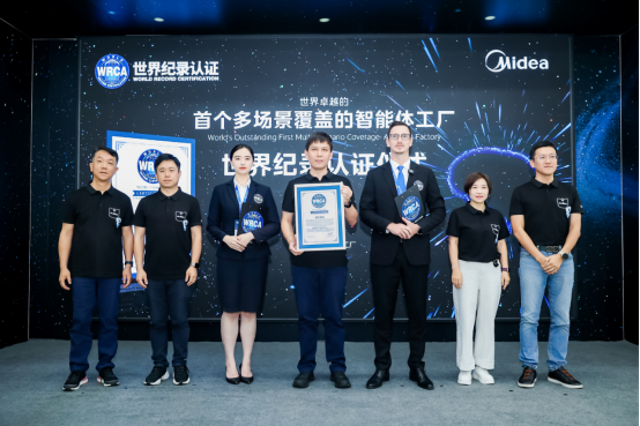

Photo of the certification ceremony

Chinese appliance maker Midea, based in Guangdong, is using AI to revolutionize its factories. At its washing machine plant in Jingzhou, central China's Hubei province, the company has introduced an "AI agent factory," a facility where humanoid robots, robotic arms, and autonomous machines work together under a central AI system.

The project recently received certification from the London-based World Record Certification Agency (WRCA), which praised its scale and the use of AI agents operating across multiple scenarios. Currently, 14 AI agents manage 38 key production scenarios, from scheduling and logistics to quality checks and equipment maintenance.

The robot "Melo" working in the factory

At the heart of the system is Midea's "Factory Brain," a smart AI platform that allows machines to communicate, make decisions, and self-correct. According to the company, tasks that once took hours of human effort can now be completed in seconds. Efficiency has increased by more than 80%, and scheduling response times have improved by 90%.

On the factory floor, this means faster inspections and more flexible assembly lines. Quality checks that once took 15 minutes now take just 30 seconds using AI-assisted glasses linked to design blueprints. Robots can automatically identify different washing machine models on a mixed line and adjust in real time, enhancing both speed and accuracy.

Midea staff showcasing AI-assisted glasses

Midea is also testing humanoid robots to advance automation further. Its in-house model, "Melo," handles repetitive tasks like inspection and equipment monitoring, feeding information back into the "Factory Brain." In addition, autonomous mobile robots (AMRs) transport materials across the factory, rerouting automatically when obstacles appear, which is a step toward the so-called "dark factory," where production can run with minimal human presence.

For Midea, the Jingzhou plant is more than a showcase. Executives say the company plans to replicate the model across its global manufacturing network, integrating AI-driven coordination and robotics from Asia to Europe. "This is a new kind of factory," said Zhang Xiaoyi, Midea’s Chief Digital Officer. "Every element of production — people, machines, and materials — is now intelligent and interconnected.”

Autonomous mobile robots (AMRs) working in the factory

Industry analysts view this as part of a broader shift in global manufacturing. As companies seek greater resilience and flexibility, AI-enabled factories promise faster adaptation to changing demand, lower costs, and more consistent quality. While the widespread use of humanoid robots in manufacturing remains experimental, Midea’s pilot demonstrates how combining embodied AI with a centralized decision-making system can help overcome key bottlenecks.

The rollout showcases how a Chinese manufacturer is moving from follower to pioneer in smart industry. If successful, the AI agent factory model could become a blueprint for the next generation of factories worldwide.

Reporter/Script | Li Muzi

Photo | Midea

Videographer/Video Editor/Poster | Guo Hongda

Editor | Hu Nan, James Campion, Shen He